Today, the machine industry is unthinkable without modern CNC machines. This technology is evolving every year and new advancements are emerging. This applies to both the software and hardware parts. This particular technology was once available only to large companies.

However, in 2024 it’s available to almost everyone – because thousands of machines are based on this technology. We will reveal to you some of the main principles on which these machines work – and reveal to you why the CNC router is an important part of these devices.

What Are CNCs Used For?

Computer Numerical Control machines are robotized processing devices that fabricate modern segments or elements for industry without a direct human intercession. These devices use encoded guidelines that will be sent to an intern computer – permitting processing plants to deliver parts rapidly and proficiently.

There are various kinds of CNCs – from those with drills to those that have plasma cutters. Therefore, they can be utilized to make a wide scope of industrial parts. Although they are mainly used within the industry production – most of these machines can be found in the home version.

Types Of CNCs

The most known and widely recognized are processing milling, grinding, and lathes machines. Mills naturally cut material, which also includes metal, utilizing a cutting axle that can be turned to various locations and profundities – as indicated by the directions of PC. Such machines contain computerized apparatuses that turn to shape the material.

They are regularly utilized for cuts of requesting geometry on even pieces, for example, cones and rollers. The grinders process materials utilizing a spindle and afterward form the ideal shape. They are anything but difficult to program and are regularly utilized for ventures which don’t require exactness in processing or turning.

CNC Machine History

CNC machines developed from NC machines (numerically controlled machines) where data was not put as entire projects in machine control – but partially loaded from drilled tapes. The advancement of CNC innovation started around the mid-1970s. This made it conceivable to support mass and individual creation, through essentially quicker and progressively exact developments of blades and other tools.

Today, the industrial business is practically incomprehensible without the presence of CNCs. The extent of their application is wide. They are utilized for processing of metal, wood, plastic, stone, glass, etching, toolmaking, demonstrating, etc.

Programming And Operation

With the assistance of some appropriate CNC programs, the model we need to make is converted into machine language comprehended by the machine. That language or G-code really creates the directions of each point that the blade needs to cross.

Notwithstanding being controlled by a computer software, the CNCs comprise a machine (milling, lathe, router), a coordinating engine, driver, a main computer, and a programming bundle. There are additionally CNC routers and milling machines and lathes. Such devices and components are also very important for the appropriate functioning.

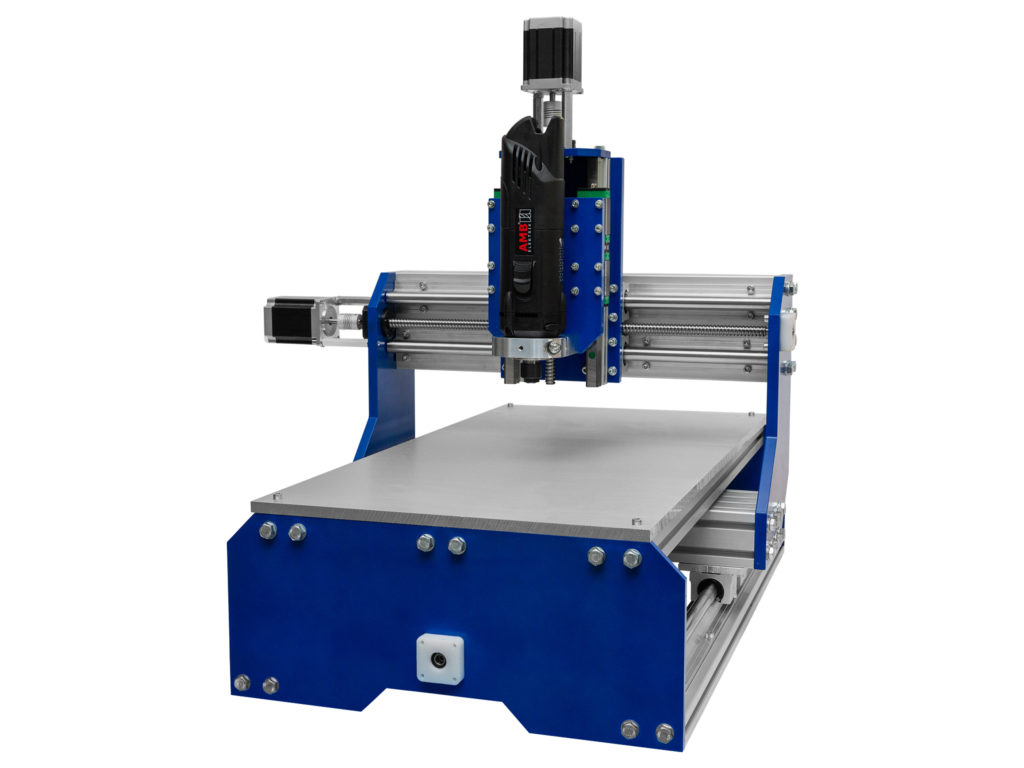

CNC Routers

These are machines of littler and lighter development and are utilized for engraving and preparing of milder materials, for example, mediapan, particleboard, compressed wood or plastic. Such machines are very quick and have a high-speed, and as a result of their small measures and high-speed – they are appropriate for workshops and small or medium production.

We can find various routers on the market utilized for various types of materials – because every material has its different qualities and shortcomings. Numerical PC controlling insinuates programs which are used in order to control the working of the router itself.

Such machines are used to make models or various examples. They are associated with a table – so they use PC programming to assist them with removing components from the parts of wood or metal in a specific shape or structure. The routers are by and large connected with a structure with 3 or 4 engine speeds. 4-engine structures give some propelled speed growing accuracy.

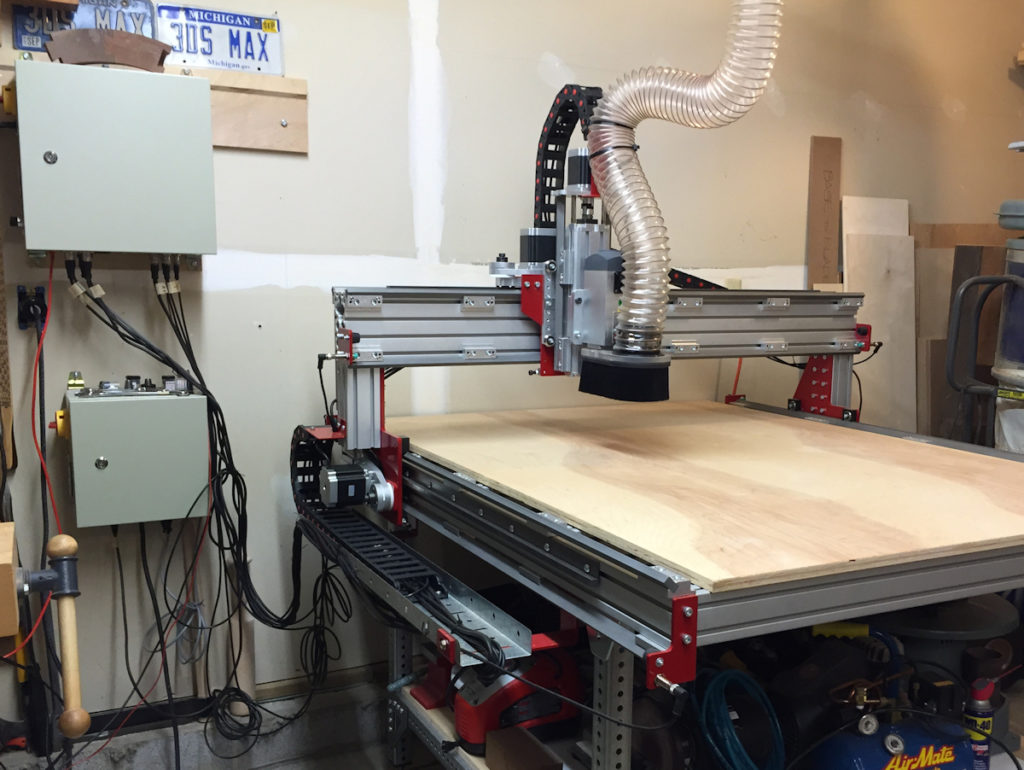

Distinct Kinds Of CNC Routers

Various kinds of routers are offering a wide degree of instruments and mechanical gathering holders. Such frameworks are proposed to permit experts to rapidly turn toolsets to various basics. The more observable the adaptability – the speedier the development will be finished. As indicated by Elephant CNC, while utilizing routers, it is fundamental to comprehend the thing that controls its advancement.

The last sharp edge hugeness and cutting zone are compelled by the PC, and CNCs mechanical engineers must be qualified with the thing introduced on the contraption. A PC program is open for a course of action of materials, with restriction and information about the material that can convey the best yield over various methodologies.

Protection Of Materials

Two strategies are usually used to ensure the material when utilizing a router: suction-dependent on a fire, or a vacuum framework. Many of these machines offer just a single strategy. Every technique has explicit applications so it could be increasingly productive. Suction plugs are regularly used to hold materials with the goal that it very well may be turned and controlled varying. A suction-based framework is suitable when the item should be cut. Cutting is while making a notch in some strong material.

Tile or plate embeds are also a vacuum-suction technique utilized on a low-thickness table. With such a strategy, the elements can be put anyplace on the table and held firmly by the suction vacuum made below the table surface. This kind of framework is somewhat more costly than suction-plugs on the grounds that the motor is required to make a more prominent degree of suction over a more extensive region.

Advantages Of Using CNCs

The advantages of using CNC machines in machining materials compared to conventional machines are numerous. We will highlight only a few of them:

Using CNC Machines Reduces Labor Costs

Experienced CNC programmers and operators are people who understand the machine, the way it works and the processing technology. Sometimes, a highly trained CNC machine requires a highly trained person.

Large Series – Top Quality

Because this kind of machine is operated via a computer, through high-quality components – repositioning and machining accuracy have been brought to high accuracy to achieve strictly defined machining tolerances. These state-of-the-art machines meet all the standards of high-quality machining in which high precision and tolerance are taken into account.