Are you looking to automate in 2024? This is an exciting period for industrial automation. Why? Because you can find new, cheaper, and more advanced solutions in the market. Compared to a decade ago, there is much more variety and easily available industrialized robotic solutions today making automation within reach even for SMEs.

Articulated robotics form the bulk of industrial bots in use today. Chances that any buying decision you will be involved in the future regarding work automation will include articulated systems.

What Are Articulated Industrial Robots?

Articulated industrialized robots operate like a human arm using a series of jointed arms connected to a flexible base. Due to their flexibility and versatility, articulated industrial bots have the widest range of applications across industries.

These robots can be small and simple with two joints. Moreover, they can be large with up to ten joints. It all depends on their application and the type of operation. This is mainly why both big and small companies can afford to automate with this robotic system regardless of their budget or needs. A big percentage of industrial robots for sale today comes under this category.

Articulated Industrial Robot Advantages

Some of the key advantages of modern articulated robotics used in manufacturing settings include:

- Simple to set up, operate, and maintain because of their modular nature. Each limb can be taken off and fixed back at the joint without having to de-assemble the entire robotic arm.

- Their flexibility and modularity make them more versatile meaning they can be used for a wide array of functions and can be repurposed at any time.

- Availability- most of the industrialized robots in the market today are these. There are robots of all sizes, budgets, and applications as well as parts, end of arm tooling, etc.

Common Applications for Articulated Industrial Robots

While these robots can be used for pretty much any application in all industrialized setups, they tend to excel in the following:

- Pick and place operations

- Machine tending

- Molding

- Painting

- Part handling

- Hazardous material

- Cutting

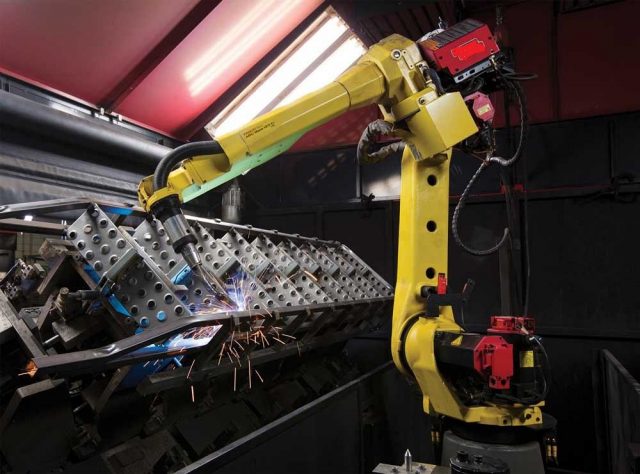

- Welding

- Parts assembly, among others

A new trend in the articulated robotics sectors is the introduction of collaborative robots. These new bots have the same assembly used in the traditional industrial articulated type but can be used safely with human operators. Collaborative robots promise to change how industrial automation works and the role of the human in the whole setup.

What to Consider When Purchasing Articulated Industrial Robots

1. Complexity and Capability

Articulated industrial robotic machines come in all sizes, shapes and can have as many as ten joints and arms that are several feet long. The more complex the robot, the higher the initial and operational costs. This is, perhaps, the most important factor to consider when trying to automate. In most cases, you will need expert opinion either from within your organization or from the manufacturer to come to a decision.

Since this robot type is used for a variety of functions, you can save a lot of money by purchasing generic bots that can be disassembled or repurposed based on current needs. Some manufacturers even offer modular systems that can be modified as frequently as desired. Newer articulated robotic arms are also easier to program and set up as compared to traditional ones.

2. Application

While some articulated robots can be used in many applications, you should ideally have a clear picture of what you want to do with the robot before you make a purchase. This will also inform what size, and type of robot to buy. For instance, collaborative robotics work best where human-robot interaction is required.

Similarly, there are other types of robotics that have specific features and functional uses. Thus, because of the higher efficiency and speedy working capability, robotics is in excessive use in the industrial sector.

3. Integration

You also need to consider if the articulated robot will integrate with your existing system for an easy transition. Some industrial robots require special mounting, fencing and can only be paired with specific industrial systems.

All in all, the use of robots in automation is slowly becoming a standard across many industries. Thanks to falling prices and modern solutions, it is now easier for anyone with a need for automation to get industrial robots that suit their needs. It’s time to automate!

Difference between articulated and other types of robotics

The robotic industry is not limited and every single robot has its specified operational use. So, here are the four product segments for the industrial use of these machines. Every single one of them has its specific use in specific industries.

1. Articulated robot

Articulated robots are most suitable for material handling and general assembling functions. Furthermore, the manufacturing industries prefer using them. The main role of articulated bots is in sealing, welding, picking, spraying, painting and cutting. Furthermore, they also assemble things and can carry out material handling.

Furthermore, the market of this segment showed amazing growth in 2024. It reached $1.28 billion last year.

2. Cartesian robot

Cartesian robots offer a high degree of mechanical rigidity, accuracy and repeatability because of their linear movement. Furthermore, these robots have a consistent payload capacity. Therefore, they are used in industries to carry and move heavy loads.

In addition to moving and carrying heavyweights, they also have other uses. Therefore, the metal industry is quite fond of Cartesian robotics. Their work responsibilities involve loading, unloading, cutting, bending, drilling, welding, stamping, forging and casting. Therefore, they easily deal with most of the workload and reduce the human workforce and efforts.

3. SCARA robot

Unlike Cartesian, SCARA robots are based on a 4-axis design. Therefore, they offer multiple directional movements. Furthermore, the most common use of SCARA is in high-speed kitting, packaging, assembly and material handling.

Furthermore, electronics need precision and careful techniques. Therefore, the electronics and electrical industries also use SCARA robots for their work efficiency.

In addition to this, SCARA is also quite useful in spray painting and welding. Therefore, the automotive industry also uses them for spray painting applications, for pick and place things and for welding.

4. Others

Other robotic applications involve cylindrical, parallel and delta bots. Their use is not limited to specific operations. But the most common use is for material handling and packaging.