Automation and machine activity is a cycle that has been advancing for countless years. That made the working cycle much faster, human errors are evaded – and additionally, the degree of security at work is raised. Some of the first machines with numeric controls showed up during the mid-twentieth century. These machines can perform various types of work – for example, milling, sawing, drilling, etc.

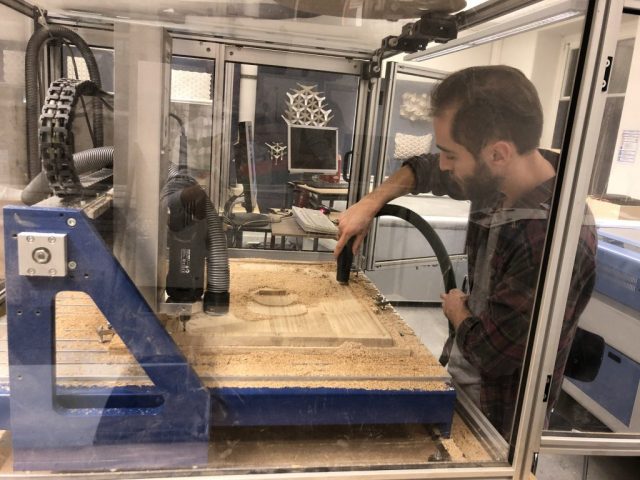

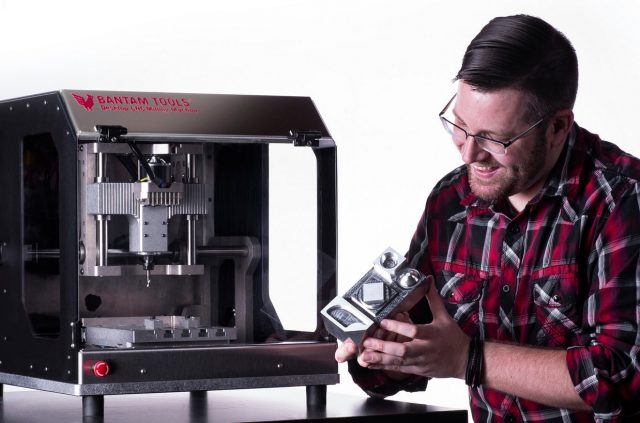

Based on their capabilities, today CNC machines have their application essentially in traditional industries – which are centered around large-scale manufacturing and serial production. Probably the most commonly utilized are CNC milling machines. And what should beginners in a CNC milling machine know before they start working on them? Here are a few things.

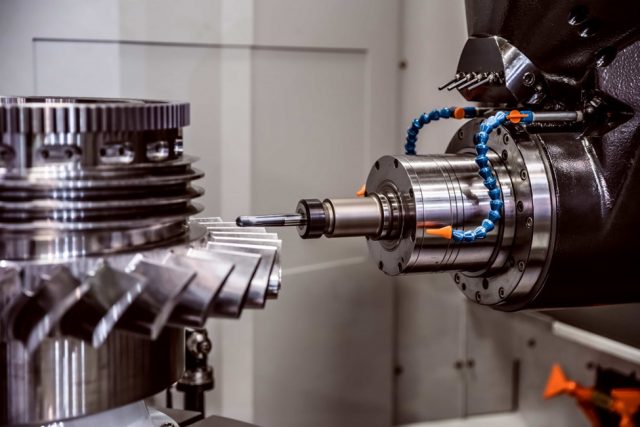

How Does A CNC Milling Machine Work?

CNC stands for Computer Numerical Control. This means that the computer converts the Computer-Aided Design software into numbers. These numbers are the coordinates of the graphic (x, y, z) – and they control the movements of the tools that process the material. In this way, the computer manages the milling, cutting – as well as shaping of the material being processed. Milling can best be described as horizontal drilling. When drilling, the tool moves along the vertical axis (z) – and when milling, the tool also moves along the horizontal axis (x, y). So with the vertical feed, the tool enters a certain depth – and then with the horizontal feed, the material is processed according to particularly given coordinates. The important thing is to note that the material being processed is stationary – and only the tool is moved.

What CNC Milling Machines Can Be Used For?

Depending on the type of CNC milling machine, it can be used for processing wood, artificial materials – and also light and heavy metals. Some of the milling machines are almost universal – and can process wood, artificial materials, but also light metals. When processing light materials, an operator must take care to keep the Z coordinate as small as possible (for example, only up to 15 cm) – due to high torsional forces. When processing light metals – the tool cooling fluid must also be used. For quality CNC milling machine, visit summitmt.com.

5 Things People Need To Know Before Start Working On CNC Milling Machine

For many industrial companies, it is very hard to find and hire qualified operators when it comes to CNC machinery. Indeed, sometimes it can be hard to find employees who have more experience in a manufacturing plant. Instead, they have to hire those who simply have the interest and are eager to learn. That ultimately means training the staff from the very beginning. Having this in mind, take a look at 5 things that potential CNC machinery operators need to understand and be alerted to – before they start to work on a particular CNC machine.

1. Getting to know the job on the machine

CNC machines have basic characteristics – that the operators must get acquainted with. According to elephant-cnc, beginners in this business must be trained first of all what the control panel of CNC machine tools looks like, what is CNC router, which programs are used for programming CNC milling machines, what are the processing operations on these machines, which are basic and additional features of CNC software – and more. Awareness of the concept of safety at work, the role, and the importance of safety and health at work is important in dealing with this business. Candidates who are trained to work on these machines – are prepared to notice all the factors of injury in the workplace.

2. Production plant safety

The most important thing that newcomers to production should comprehend – is that a production facility can be quite a hazardous place. You need to take two areas into consideration: The safety of the equipment which employees use – and the safety practices that they must stick to. Besides, alert them to any individual safety matters in the production facility.

3. Mathematics

This is something that every CNC milling machine operator should know – but it is actually pretty simple. However, you should make sure that new users can use the calculator to perform basic arithmetic operations. People who are working on CNC milling machinery should be able to repeat simple math calculating, avoiding making errors. Also, make sure that your employees know how to read the numeric values correctly – which is, in microns. Turn on the conception of negative numeric merits – since CNC technician settings include also a certain polarity.

4. Interpreting drafts

People who are working on CNC milling machinery have to know how to explicate a 3D object being worked on a machine from a row of 2D displays on a technical drawing. This includes a good comprehension of line types – as well as orthographic layouts. Luckily, CNC technicians will have a finished workpiece that they can use for comparing it afterward. CNC technicians also need to know how to interpret dimensions – so they can estimate the size of each workpiece attribute.

5. Interpretation of tolerance

The beginners in utilizing CNC milling machines should understand the fact that every object attribute – has something that we call a permissible error. That is something that may be specified or sometimes even implied. CNC technicians have to look especially for the type of tolerance that refers to dimensions. That’s why it’s called a dimensional tolerance. Attributes that go with a certain type of tolerance – operator can set up easily. If it’s about size tolerance, technicians can determine them in several ways – but they should be focusing on the procedures within the company they work in. However, technicians also have to know the expected values in case if any adjustments are needed – and this also happens quite often.

What Every CNC Milling Machinery User Knows: Benefits Of Such A Job

Perhaps the biggest advantage of this profession is the wide range of its application – because the need for experts in this field is growing. When you become a CNC operator, you can work in machining companies, in plants for maintenance and production of machine parts and devices, etc. This profession also offers you the competencies to independently perform handling classic and numerically controlled machine tools in production. You can independently create simpler technical drawings and sketches – while you will be able to read the more complex ones and make workpieces according to them. For all calculations, sketches, and drawings, you will use modern computer programs – especially those related to drawing on a computer. In a word, for many, this is the job of the future – and your effort will pay off.