In the world of auto restoration, precision, and innovation go hand in hand. One remarkable advancement that has revolutionized the field is the use of Paintless Dent Repair (PDR) tools.

These tools have brought a new level of finesse to the process of restoring vehicles that have been in accident or damaged some other way, ensuring that dings and dents are eradicated with precision while preserving the vehicle’s original paintwork.

In this blog post, we will delve into the evolution, benefits, techniques, and impact of PDR tools on the world of auto restoration.

History: Evolution of PDR Tools in Car Repair

The journey of PDR tools dates back to the mid-20th century when car manufacturers sought efficient ways to repair minor dents without the need for extensive paintwork.

Over time, skilled technicians developed specialized tools to manipulate and massage dented panels back into shape, gradually giving birth to the concept of Paintless Dent Repair.

The method gained popularity, not only for its effectiveness but also for its ability to reduce repair time and costs significantly.

Defining Paintless Dent Repair and Its Benefits

Paintless Dent Repair, as the name suggests, involves the art of repairing dents without the need for repainting. Skilled technicians use an array of precision tools to access the dent from behind the panel and gently massage it back to its original form.

One of the most significant advantages of PDR is its ability to maintain a vehicle’s factory finish. This technique eliminates the need for body fillers or extensive sanding, preserving the integrity of the vehicle’s exterior while restoring its aesthetic appeal.

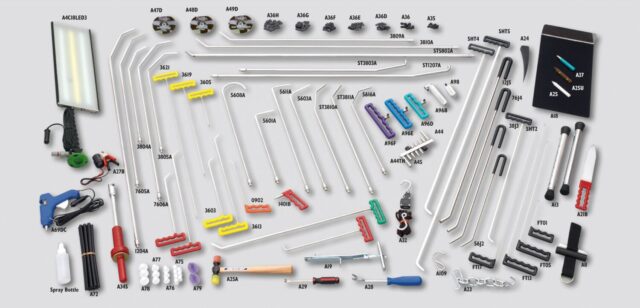

Tool Types: Explore Various Tools and Their Functions

A variety of specialized instruments, each with a specific function in the dent repair process, are at the disposal of professionals. These tools have been painstakingly engineered to accommodate a variety of dent kinds and panel shapes, from whale-tail tools that reach dents in confined locations to pivot-headed picks for precise adjustments.

Another method is called “glue pulling,” which is using tabs and adhesives to remove dents from the outside. PDR is a flexible option for a variety of dent sizes and complexities thanks to this equipment and the technician’s experience.

Precision Technique: How PDR Ensures Dent Removal Without Paint Damage

At the heart of PDR lies an intricate dance between the technician and the tools. The process requires finesse, patience, and an in-depth understanding of the vehicle’s anatomy.

Technicians meticulously assess the dent’s size, location, and depth to determine the best approach. By strategically applying pressure and using specialized tools, they coax the metal back to its original shape without disturbing the paint.

This level of precision not only restores the vehicle’s appearance but also upholds its value by maintaining its original factory finish.

Professional Application: Role of Skilled Technicians in the PDR Process

While PDR tools are essential, it’s the skill and experience of the technicians that truly bring a vehicle back to its former glory. A seasoned professional possesses an intuitive understanding of mental behavior, knowing exactly how much pressure to apply and where.

This expertise is particularly crucial when dealing with complex dents that require a delicate touch. The ability to assess the damage accurately and select the right tools for the job is what sets skilled technicians apart, making them artisans in the world of auto restoration.

Industry Impact: PDR’s Influence on Auto Restoration Standards

The emergence of PDR tools has significantly raised the bar for auto restoration standards. As vehicle owners become more discerning about the preservation of their investments, the demand for non-invasive, paint-friendly dent repair methods has surged.

PDR has not only met this demand but has also redefined customer expectations. With its ability to deliver seamless results, PDR has become the go-to choice for dealerships, body shops, and individual vehicle owners alike.

Sustainability Benefits: Eco-Friendly Approach of PDR

Paintless Dent Repair (PDR) is not just a technological innovation; it’s also an eco-friendly approach in auto restoration. This method significantly reduces the environmental impact compared to traditional repair methods. Traditional methods often involve toxic body fillers, solvents, and paints, which release harmful chemicals into the environment. In contrast, PDR eliminates the need for these materials, thus reducing the emission of volatile organic compounds (VOCs).

Whether it’s restoring a classic car or repairing a modern vehicle, utilizing high-quality parts from trusted suppliers like DB electrical ensures both performance and eco-friendly practices.

Comparisons: Contrasting PDR With Traditional Dent Repair Methods

A noteworthy aspect of tools is the stark contrast they pose to traditional dent repair techniques. Conventional methods often involve sanding, filling, and repainting, which not only extend repair times but also introduce the risk of color mismatches and diminished vehicle value.

PDR eliminates these concerns, offering a quicker, more efficient, and cost-effective alternative. By adhering to the philosophy of ‘less is more,’ PDR tools exemplify the marriage of technology and craftsmanship in modern auto restoration.

Technological Advances: Innovations Shaping the Future

As technology continues to advance, so do tools. Cutting-edge innovations, such as digital imaging systems and precise measurement tools, are augmenting technicians’ capabilities.

These advancements enable technicians to visualize the dent repair process more accurately and improve their overall efficiency. Additionally, the integration of AI-driven algorithms assists in predicting optimal tool selection and pressure points, ensuring consistently exceptional results.

The evolution of PDR tools is a testament to the industry’s commitment to pushing boundaries and achieving ever-greater levels of excellence.

Training and Skill: Importance of Mastering Techniques for Success

While PDR tools offer an incredible advantage, they are only as effective as the technicians who wield them. Mastering techniques requires dedication, training, and continuous skill refinement.

Aspiring technicians undergo rigorous training programs to understand the intricacies of dent types, metal behavior, and tool application. Beyond technical skills, professionals develop an artistic eye, knowing how to manipulate shadows and contours to achieve flawless outcomes.

The investment in skill development pays off not only in the quality of repairs but also in the reputation and success of the technician.

Conclusion: PDR’s Transformative Role in Modern Auto Restoration

In the realm of auto restoration, the journey from dings to brilliance has been significantly expedited by the ingenious use of PDR tools. From humble beginnings to a pivotal role in shaping restoration standards, PDR tools have proven their mettle.

These tools embody precision, innovation, and a commitment to preserving a vehicle’s aesthetic and financial value. As technology continues to propel the industry forward, one thing remains certain: the artistry of PDR and the skilled technicians behind it will continue to play a transformative role in modern auto restoration, ensuring that every vehicle can shine brightly once more.